Our Product Range

AMPCO METAL offers a full range of aluminum bronze and other copper based arc welding alloys that are

suited for a wide range of applications

Need help choosing the right welding product?

About AMPCO Welding Products

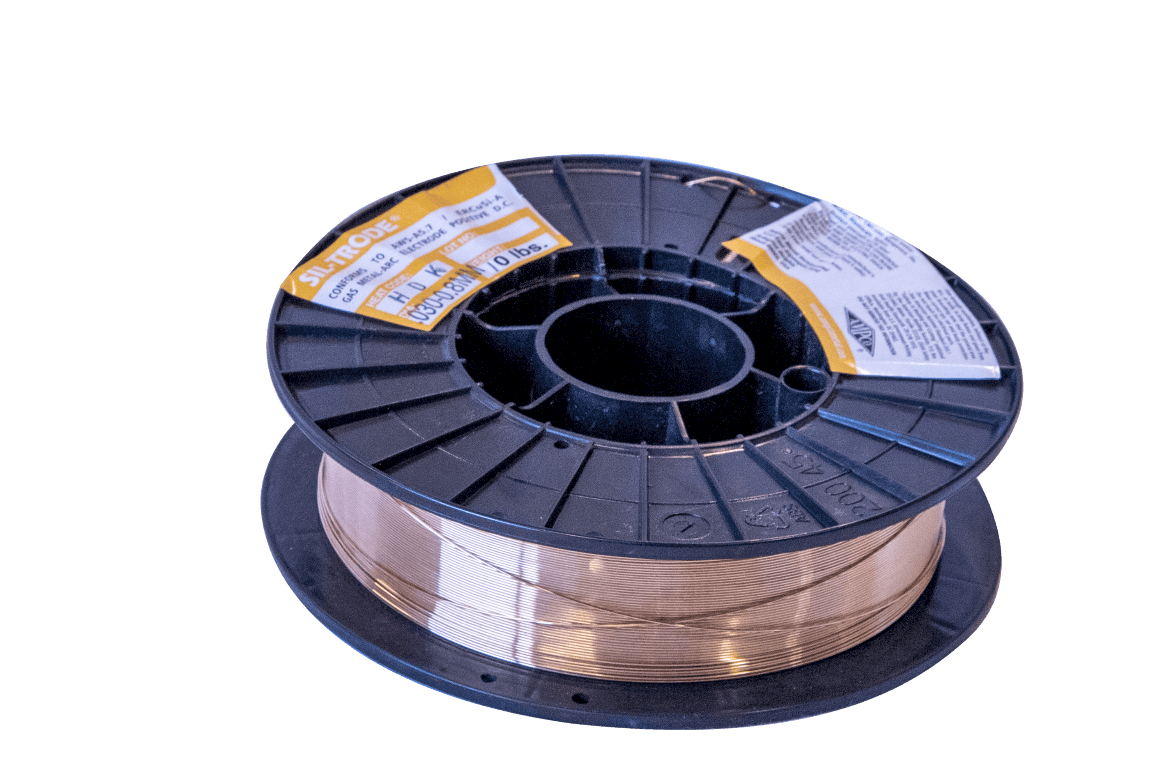

AMPCO METAL offers a full range of aluminum bronze and other copper based arc welding alloys that are suited for a wide range of applications. AMPCO-TRODE® 10 (AWS Class ERCuAl-A2, ECuAl-A2) is the most versatile welding filler metal in our extended family of aluminum bronze alloys. This alloy is used for joining, as surfacing for a bearing or wear surface, as surfacing for corrosion resistance, joining dissimilar metals, and for maintenance and repair.

Aluminum bronze alloys AMPCO-TRODE® 7, 10, 150, 160 are recommended for welding aluminum bronze of similar compositions, and as surfacing for bearing surfaces on steel for metal to metal wear. These alloys produce a deposit with an average hardness of 125 through 166 Brinell. They are available in MIG spooled wire, TIG filler rod and coated electrodes.

AMPCO-TRODE® 40 is a manganese-nickel-aluminum bronze alloy and AMPCO-TRODE® 46 is a nickel-aluminum bronze alloy available in MIG spooled wire, TIG filler rod and coated electrodes. These alloys produce deposits of high strength and are used for welding ship propellers, turbine runners, cast nickel-aluminum bronze ship fittings and pump housings. Their principle attribute is for applications where high resistance to corrosion, erosion and cavitation is essential.

For applications that require resistance to wear or for very high metal to metal wear hardness requirements, AMPCO-CORE® 200, 250, & 300 will produce deposits with an average hardness of 183 – 364 Brinell. AMPCO-CORE® is a flux core MIG wire. These products are ideal for rebuilding aluminum bronze dies or fabricating the ferrous dies used for forming or drawing low carbon, aluminum, titanium and stainless steel. Dies made of hard aluminum bronze have surprising resistance to scratching, galling, and seizing and last longer than steel dies.

COPR-TRODE® is a deoxidized copper alloy developed to provide dense, high quality deposits with relatively high (40% IACS) electrical conductivity. With the inert gas welding processes, COPR-TRODE® is preferred for fabricating deoxidized copper and repair welding of copper castings. It may also be used to weld galvanized steel and deoxidized copper to steel where high strength joints are not required and to overlay surfaces to resist corrosion.