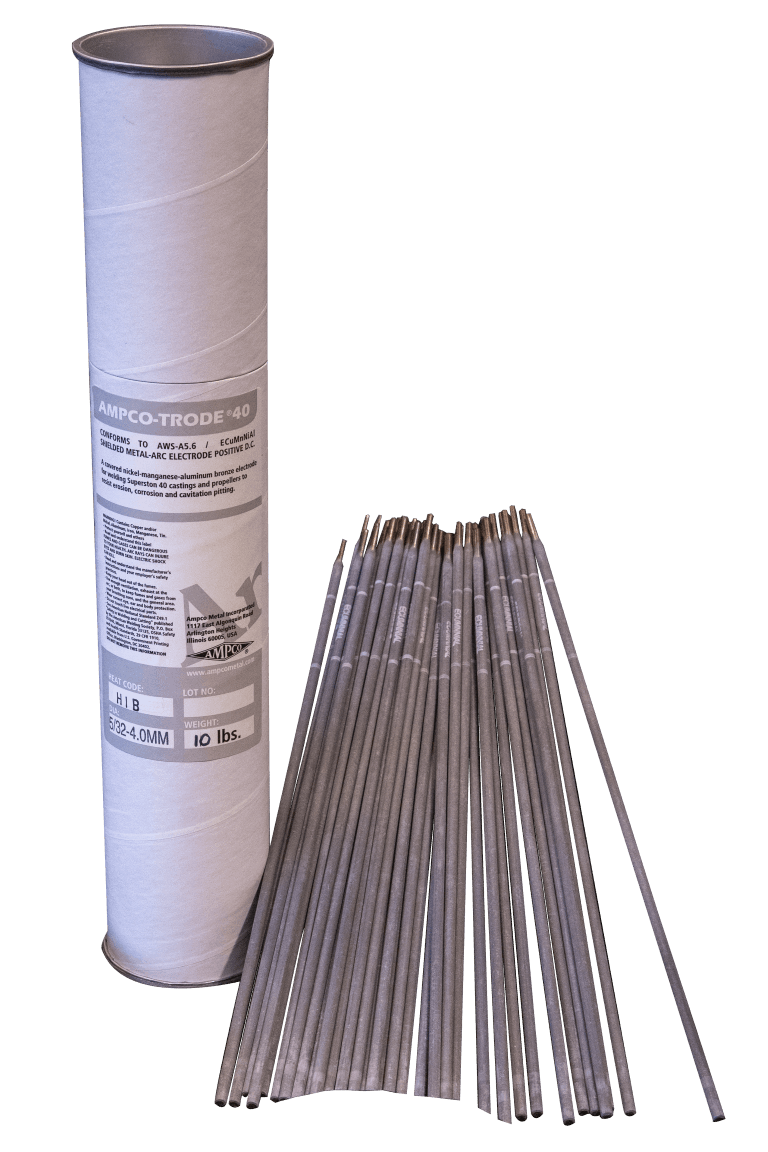

AMPCO-TRODE® 40

AWS A5.6 – ECUMNNIAL

AWS A5.7 – ERCUMNNIAL

Description and Application

AMPCO-TRODE® 40 manganese-nickel-aluminum bronze is available in coated electrodes, bare filler metal rod and wire for welding cast ship propellers conforming to MIL-B-21230, Alloy 2 for high resistance to corrosion, erosion and cavitation.

AMPCO-TRODE® 40 also exhibits good ability to join dissimilar metals.

Typical Applications

| Ship propellers | Marine components | Welding cast iron |

| Joining dissimilar metals |

AMPCO-TRODE® 40 Coated

| Limiting Chemical Composition | |

| % (deposited weld metal) | |

| Copper* | Balance |

| Aluminum | 7.0 – 8.50 |

| Iron | 2.0 – 4.0 |

| Nickel | 1.5 – 3.0 |

| Manganese | 11.0 – 14.0 |

| Silicon | 1.5 max. |

| Others | 0.50 max. |

| * including silver |

| Mechanical Properties | |

| (Nominal all-weld metal values) | |

| Tensile Strength ksi | 95 (655 MPa) |

| Yield Strength ksi | 56 (386 MPa) |

| Elongation % in 2″ (51mm) | 27 |

| Reduction of Area % | 38 |

| Hardness (HBW 10/3000) on 1/4″ (6.4mm) deposit | 185 |

Specifications

AWS A5.6 Class E CuMnNiAl

ASME SFA 5.6 Class E CuMnNiAl

ASME SFA 5.6 Class E CuMnNiAl

AMPCO-TRODE® 40 Bare

| Limiting Chemical Composition | |

| % (deposited weld metal) | |

| Copper* | Balance |

| Aluminum | 7.0 – 8.50 |

| Iron | 2.0 – 4.0 |

| Nickel | 1.5 – 3.0 |

| Manganese | 11.0 – 14.0 |

| Others | 0.50 max. |

| Mechanical Properties | |

| (Nominal all-weld metal values) | |

| Tensile Strength ksi | 110 (759 MPa) |

| Yield Strength ksi | 67 (462 MPa) |

| Elongation % in 2″ (51 mm) | 27 |

| Reduction of Area %. | 37 |

| Hardness (HBW 10/3000) on 1/4″ (6.4mm) deposit | 217 |

Specifications

AWS A5.7 Class ER CuMnNiAl

ASME SFA 5.7 Class ER CuMnNiAl

ASME SFA 5.7 Class ER CuMnNiAl

*Hardness will vary depending on quality of the weld and experience and knowhow of the welder.

Document Download

AMPCO-TRODE® 40 Technical Data Sheet