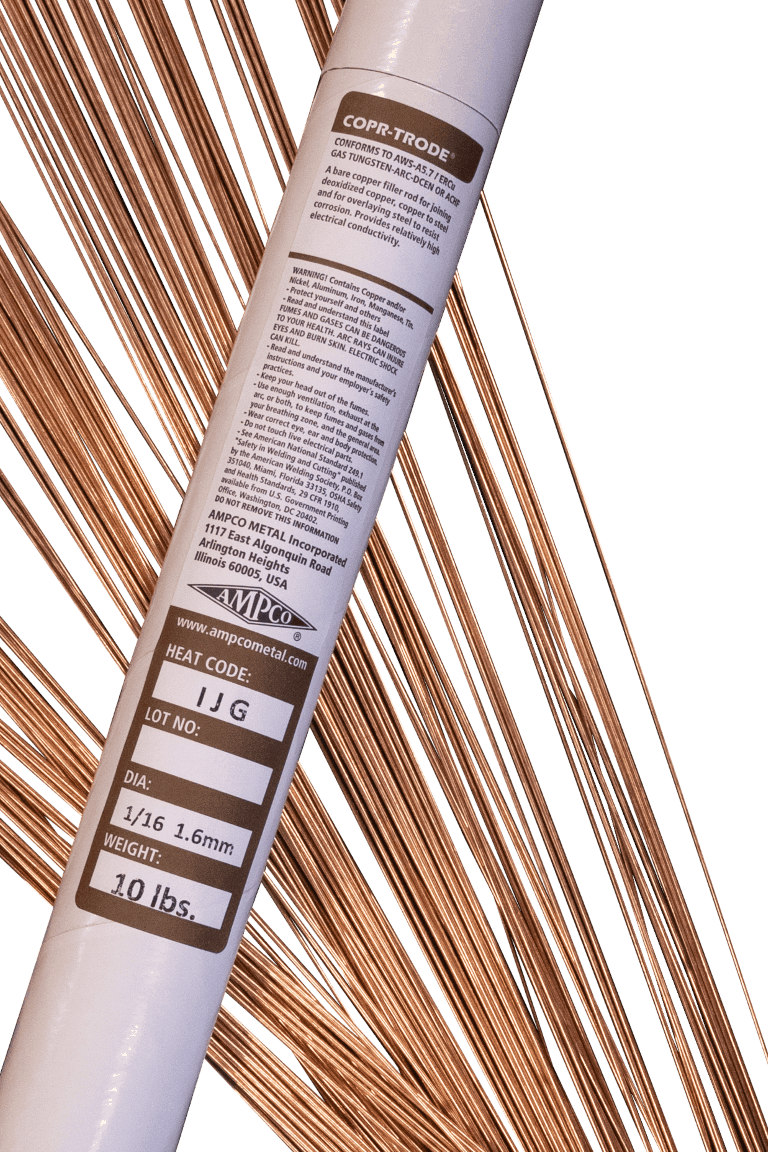

COPR-TRODE®

AWS A5.7 – ERCU

Description and Application

COPR-TRODE® is a deoxidized copper alloy developed to provide dense, high quality deposits with relatively high electrical conductivity for use in joining and overlay with the inert-gas processes.

COPR-TRODE® spooled wire and filler metal rod are used primarily to fabricate deoxidized copper and repair weld copper castings with the gas metal-arc and gas tungsten-arc processes. It may also be used to weld galvanized steel and deoxidized copper to mild steel where high strength joints are not required.

COPR-TRODE® spooled wire and filler metal rod are used to overlay surfaces to resist corrosion.

Typical Applications

| Billet molds | Conductor rolls | Heater elements |

| Copper sculptures | Steel mill electrode holders | Bus bars |

| Copper connectors |

COPR-TRODE®

| Limiting Chemical Composition | |

| % (filler metal) | |

| Copper* | 98.0 min |

| Tin | 1.0 max |

| Manganese | 0.50 max. |

| Silicon | 0.50 max. |

| Phosphorus | 0.15 max. |

| Others | 0.50 max. |

| * including silver |

| Mechanical Properties | |

| (Nominal all-weld metal values) | |

| Tensile Strength ksi | 29 (200 MPa) |

| Yield Strength ksi | 8 (55 MPa) |

| Elongation % in 2″ (51 mm) | 29 |

| Reduction of Area % | 45 |

| Hardness (HBW 10/500)on 1/4″ (6,4 mm) deposit | 54 |

| Electrical Conductivity, % IACS | 40 |

Specifications

AWS A5.7 Class ERCu

*Hardness will vary depending on quality of the weld and experience and knowhow of the welder.

Document Download

COPR-TRODE® Technical Data Sheet